-

EXPLORE FURTHER: Specialists explain why it’s always best NOT to store onions in the refrigerator

As every shopper understands, eggs come packaged in cardboard containers arranged neatly in upward-facing rows.

However, nothing compares to the disappointment of bringing them home only to find that some of these delicate items are cracked and damaged.

Currently, an unexpected new research proposes a groundbreaking method for packaging and storing eggs.

Actually, experts have found that they would fare much better lying on their side with a sideways orientation instead of an upward one.

Lab experiments at

Massachusetts

The study from the Massachusetts Institute of Technology (MIT) indicates that raw chicken eggs are less prone to cracking when dropped on their sides.

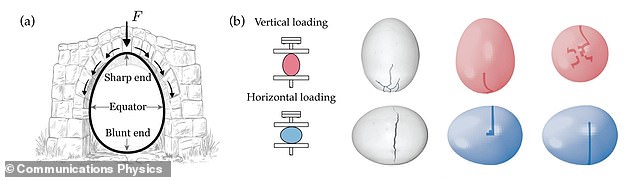

Since the ‘equator’ of an egg is more resilient to impact, the packaging ought to be improved to safeguard the two more vulnerable tips.

Moreover, if we were to lift them from a cardboard box horizontally, they would be less prone to cracking if dropped directly onto the floor.

The MIT researchers state in their paper, released today, “Eggs prove more resilient when subjected to pressure along their equatorial region,” as reported in

Communications Physics

.

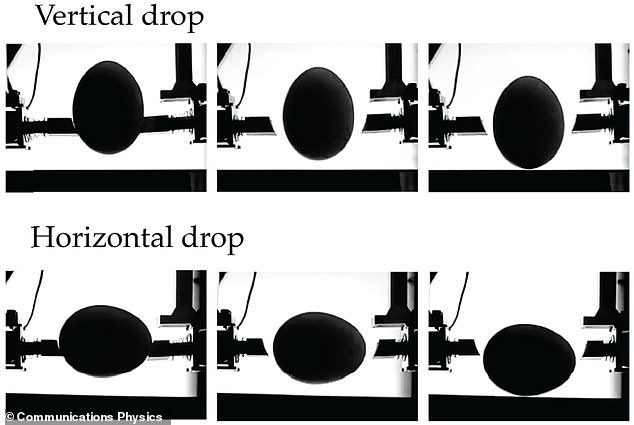

To compare how large raw chicken eggs shatter under similar conditions, the scientists performed drop tests with three different orientations: horizontal along their equator, vertically on their pointed ends, and vertically on their rounded ends.

In total, they tested 180 eggs—60 at each of the three distinct heights: 0.31, 0.35, and 0.39 inches (which correspond to 8, 9, and 10 millimeters respectively).

Should researchers discover a fissure in the shell, the egg would be categorized as cracked.

In general, they observed a ‘statistically significant reduction’ in the probability of an egg breaking when placed horizontally compared to vertically.

Fewer eggs broke upon impact at their equators compared to those hit at their poles.

On average, eggs broken when dropped vertically shattered at a lesser height of 8.66mm as opposed to those dropped horizontally, which broke at 8.9mm.

Over half of the eggs that were dropped vertically from a height of 8 millimeters cracked (whether the bottom or top end hit the ground first did not make a difference).

At the same time, fewer than 10 percent of horizontally dropped eggs broke when dropped from the same height.

An additional 60 eggs underwent compression testing to determine the amount of force needed to break them both vertically and horizontally.

Although 45 newtons of force were needed to break the eggs regardless of their orientation, the eggs placed horizontally could be compressed more before they cracked.

Scientists believe that eggs are more pliable around their ‘equator,’ which allows them to withstand greater impact in this area without cracking.

The findings likewise debunk the common misconception that an egg dropped vertically is less prone to cracking.

“We challenge the widely accepted notion that an egg is most resilient when dropped vertically on its end,” state the researchers in their paper.

These findings indicate that an egg dropped along its equator may be able to withstand higher drop distances before cracking.

In general, packaging that exposes the center of the egg more than the two ends might offer greater protection for the product.

The findings also indicate that the most effective method to break open a raw egg for culinary purposes is by tapping its top or bottom rather than striking it along the center as many people typically do.

Nevertheless, the team acknowledges that multiple material and geometric elements might influence the total robustness of an egg.

In their research document, scientists mention that the durability of eggshells holds significance extending beyond just avian eggs.

In nature, shells serve as protective coverings for soft-bodied creatures like turtle shells and sea shells, as well as for the exterior membranes of viruses and bacteria.

Future studies might further utilize these new insights in engineering contexts, examining for instance how constructions react under dynamic loading conditions.

‘The insights into the mechanical failures of these structures could therefore facilitate advancements across a wide array of applications, including the development of protective gear and drug delivery systems,’ the team explains.

Read more